The Sadhan C. Jana Group has recently published two articles featured in Microporous and Mesoporous Materials and the Journal of Colloid and Interface Science. Read and learn more about their research below.

Porous Cellulose Aerogel Microparticles Used in Drug Delivery

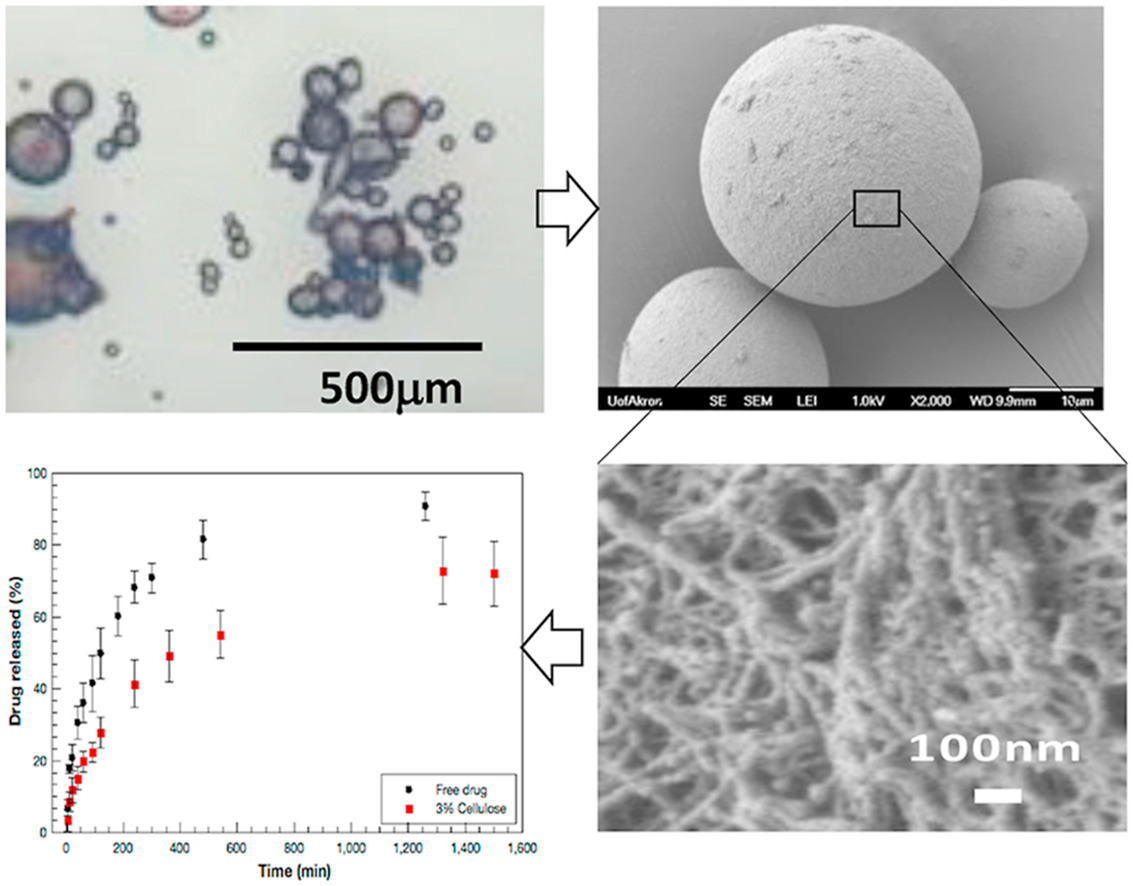

Cellulose is a biodegradable natural polymer with strong potential for delivery of drugs inside human body if they can be rendered porous and can be fabricated into micrometer size spherical particles. Conversion of cellulose into porous gel and aerogel is challenging. In this work, a sol-gel process is used in conjunction with a droplet generation scheme to obtain highly porous cellulose aerogel microparticles. Cellulose dissolved in ionic liquid and N,N-dimethylformamide mixed solvents are regenerated into gels using antisolvent ethanol. Gel microparticles of mean diameter 23–54 μm are obtained by emulsifying cellulose solutions in a surfactant-stabilized oil-in-oil emulsion system followed by regeneration in ethanol. These aerogel specimens show porosity as high as 99%, significant mesopores, and high specific surface area of 426 ± 12 m2/g. The porous architecture of the microparticles is responsible for slower release of the drug acetaminophen.

Cellulose is a biodegradable natural polymer with strong potential for delivery of drugs inside human body if they can be rendered porous and can be fabricated into micrometer size spherical particles. Conversion of cellulose into porous gel and aerogel is challenging. In this work, a sol-gel process is used in conjunction with a droplet generation scheme to obtain highly porous cellulose aerogel microparticles. Cellulose dissolved in ionic liquid and N,N-dimethylformamide mixed solvents are regenerated into gels using antisolvent ethanol. Gel microparticles of mean diameter 23–54 μm are obtained by emulsifying cellulose solutions in a surfactant-stabilized oil-in-oil emulsion system followed by regeneration in ethanol. These aerogel specimens show porosity as high as 99%, significant mesopores, and high specific surface area of 426 ± 12 m2/g. The porous architecture of the microparticles is responsible for slower release of the drug acetaminophen.

Details can be learned from the publication: Wan-Hua Lin, Sadhan C. Jana, Analysis Of Porous Structures Of Cellulose Aerogel Monoliths And Microparticles, Microporous and Mesoporous Materials 310 (2021) 110625, https://doi.org/10.1016/j.micromeso.2020.110625

Microfluidic Flows Enable Fabrication of Highly Porous Core-Shell Aerogel Microparticles

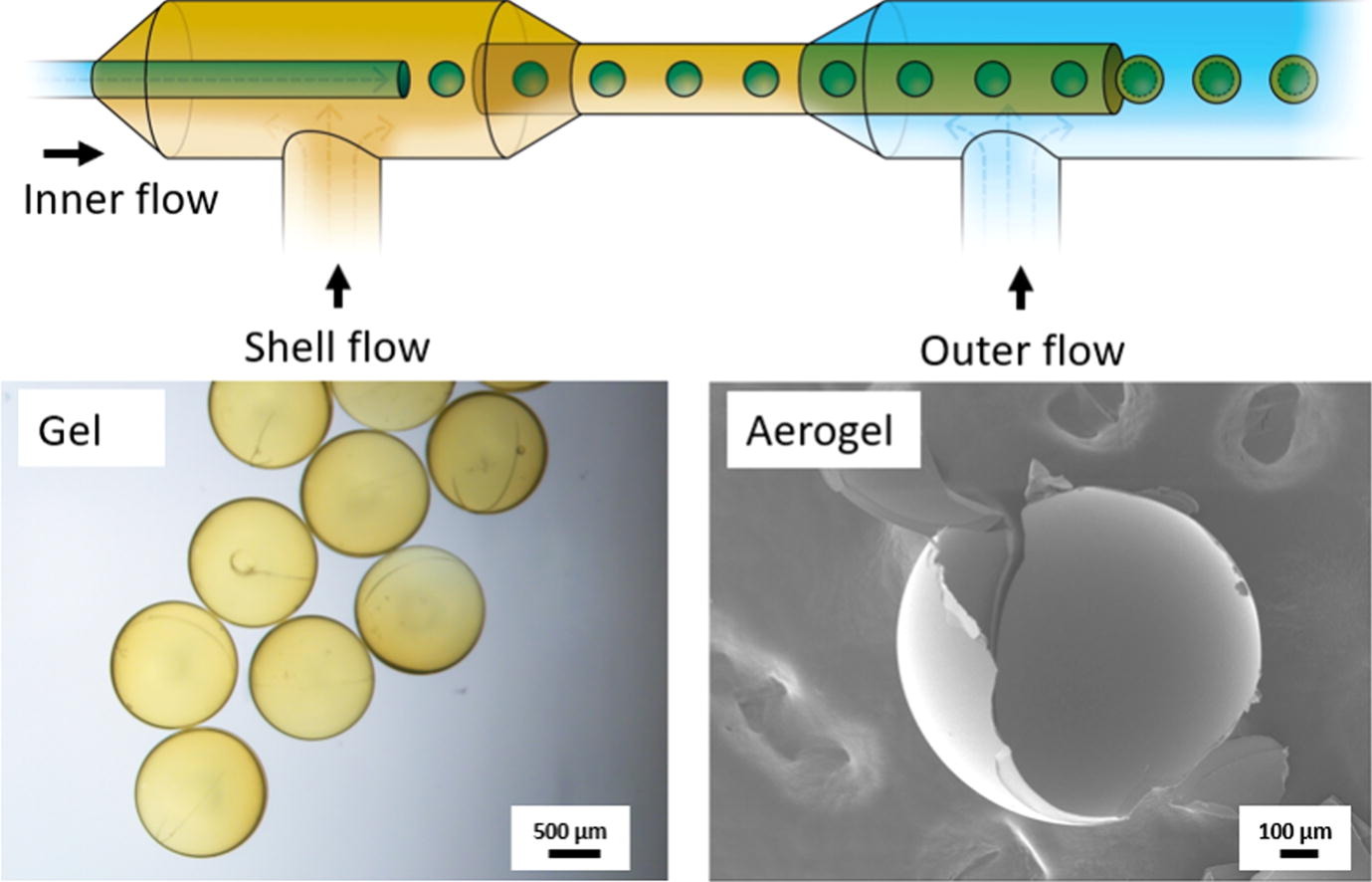

Core-shell polymer particles with porosity greater than 90% are useful in drug delivery, cleaning of noxious liquids, oil/water separation, and as catalyst support materials. Fabrication of such particles continuously is a challenge, especially if a technological application does not allow the use of surfactants. This work focuses on fabrication of core-shell polyimide aerogel microparticles with and without a surfactant via oil-in-oil-in-oil (O/O/O) emulsion system aided by a simple microfluidic device. A double emulsion is formed through sequential, stepwise emulsification of co-flowing core and shell organic liquid streams in a simple microfluidic setup. The polyimide sol, introduced as the shell liquid, undergoes accelerated polymerization in a heated silicone oil bath to yield a porous polyimide shell around silicone oil core that eliminates the possibility of droplet coalescence or rupture. The core-shell gel microparticles are then isolated and supercritically dried to obtain core-shell aerogel microparticles.

Core-shell polymer particles with porosity greater than 90% are useful in drug delivery, cleaning of noxious liquids, oil/water separation, and as catalyst support materials. Fabrication of such particles continuously is a challenge, especially if a technological application does not allow the use of surfactants. This work focuses on fabrication of core-shell polyimide aerogel microparticles with and without a surfactant via oil-in-oil-in-oil (O/O/O) emulsion system aided by a simple microfluidic device. A double emulsion is formed through sequential, stepwise emulsification of co-flowing core and shell organic liquid streams in a simple microfluidic setup. The polyimide sol, introduced as the shell liquid, undergoes accelerated polymerization in a heated silicone oil bath to yield a porous polyimide shell around silicone oil core that eliminates the possibility of droplet coalescence or rupture. The core-shell gel microparticles are then isolated and supercritically dried to obtain core-shell aerogel microparticles.

Details can be learned from the publication: Nicholas Teo, Chenxi Jin, Akshata Kulkarni, Sadhan C. Jana, Continuous Fabrication Of Core-Shell Aerogel Microparticles Using Microfluidic Flows. Journal of Colloid and Interface Science 561 (2020) 772–781, https://doi.org/10.1016/j.jcis.2019.11.053.