University of Akron provides research, testing and training to polymer industry

As part of The University of Akron’s sesquicentennial celebration — honoring 150 years of our people, place and promises — we are hosting a “Celebration of Academic Excellence” to highlight the history and future of our many academic disciplines.

In addition to cultivating the next generation of polymer experts through its doctoral and master’s degrees, The University of Akron’s (UA) polymer programs, institutes and centers provide advanced research, analytical testing, small-batch to pilot-scale processing, and workforce training services to industry, business and the community.

Polymer Workforce Training

Since 1993, Akron Polymer Technology Services (APTS) at UA has provided workforce upskilling to companies who send their incumbent employees to one-to-four-day courses and workshops on topics relevant to the large regional polymer industry, including plastics, rubber, adhesives and coatings materials and processes. Upcoming courses cover topics such as plastic packaging, vulcanization, extrusion compounding, thermoforming, vacuum forming, injection molding and 3D printing. Custom courses and on-site delivery of courses are also available. Most of the instructors are seasoned industry scientists and engineers with decades of practical experience and in-depth knowledge of their field.

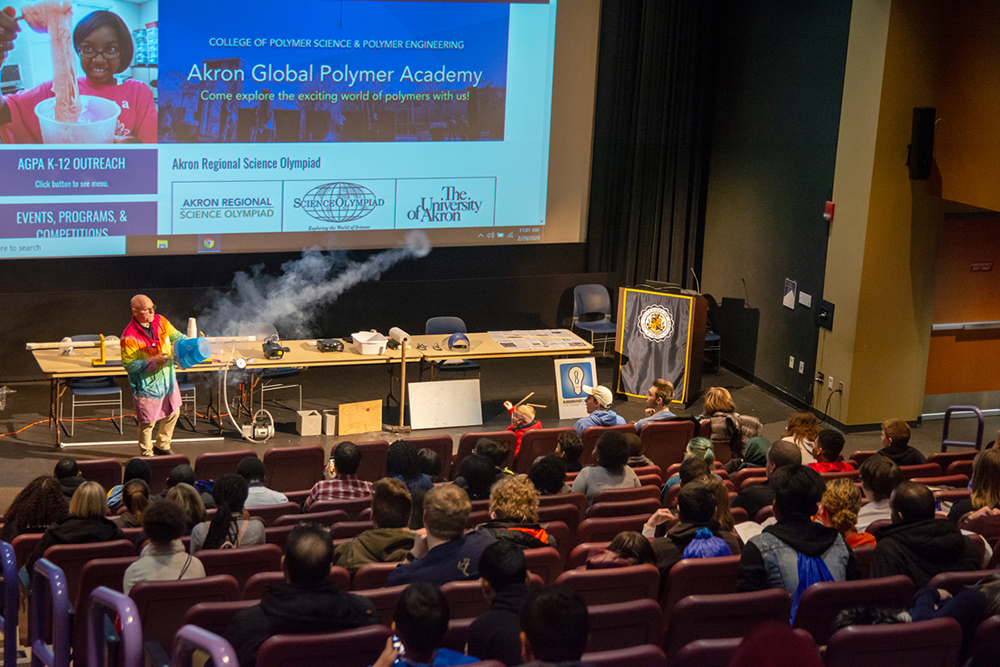

John Fellenstein, AGPA content specialist, performs engaging pressure demonstrations for more than 350 high school students, parents and Akron Public Schools teachers at Goodyear’s STEM Day co-sponsored by The University of Akron.

Since 2017, APTS has trained more than 1,300 employees from nearly 600 companies, including Bridgestone APM, PolyOne Corp., Honda R&D Americas Inc., Sherwin-Williams Automotive, GOJO Industries, Dupont and more.

Michelle Alcorn, management analyst at the Department of the Navy-PMOSSP Flight Systems, wrote: “Strategic Systems Programs Flight Systems field office in Magna, Utah (SPF B), were pleased to work directly with Penelope Pinkston, manager of APTS training, on bringing the Polymer Compounding, Formulating and Testing of Plastic Rubber Adhesive/Coating course onsite at their facility in February of 2020. This course helped to enhance the technical knowledge of SPF B’s engineers which will ultimately maximize their ability to make improved technical decisions related to rubber formations throughout the rocket motors they design and test. In addition, this course directly supports the command’s priorities of putting their people first, supporting the warfighter, and achieving their annual professional development goals.”

Processing Support for Industry and National Labs

UA also offers processing platforms for industrial development and scale-up initiatives.

The National Polymer Innovation Center (NPIC) is a facility at the leading edge of polymer advanced manufacturing, developing solutions to industry challenges in the areas of health, energy and sustainability, and supporting research for national laboratories.

APTS provides industry with practical upskilling opportunities in a variety of polymer processes.

NPIC specializes in functional multilayer film processing and advanced materials development for applications in electronics, coatings, membranes, packaging materials, and biomedical and specialty products. The center’s state-of-the-art instruments include:

- Biaxial Film Stretching

- Cast Film Coextrusion with Machine Direction Orientation

- Roll-to-Roll Solution Casting with optional Nanofiber Electrospinning

- Electromagnetic responsive processing – field-assisted alignment

- UV/IR Curing Techniques

- Additive Manufacturing – Roll-to-Roll dip coating “wet” processing

Conventional technologies covering benchtop to pilot-scale processing are also available using equipment housed in the University’s Sidney L. Olson Research Center, including:

- Compounding, Granulating, and Blending

- Extrusion

- Injection Molding

- Blown Film

- Compression Presses

A variety of customers from industry or national labs have used NPIC processing services, including NASA Glenn Research Center, ExxonMobil, DuPont, The Chemours Co., PPG Industries, Solvay, Avery Dennison Corp., Flex Films USA, Akron Polymer Systems and more.

Dr. John Harvey, scientist at Akron Polymer Systems (APS), said: “Through the NPIC, Akron Polymer Systems has obtained access to advanced processing equipment that has substantially accelerated our product development efforts. The equipment, in combination with the responsive and helpful staff, has been extremely helpful to the growth of APS’ technology portfolio.”

Polymer Testing Services

The University has served the polymer industry for more than 50 years with testing services, completing 300–400 projects per year. Since 2017, UA has provided more than $1 million worth of polymer-related testing services to more than 140 companies, including The Proctor & Gamble Co., Pfizer Inc., ExxonMobil Chemical Co. and more.

Randy Marvel, director of NPIC, gives a tour of the high-bay pilot processing equipment in NPIC to industry members.

The University’s dedicated polymer specialists and instrumentation scientists meet a variety of analysis needs for both academic and industrial partners. With millions of dollars of equipment spread across three buildings, UA’s polymer capabilities and expertise include:

- chemical analysis (GC, GPC, FT-IR, UV-Vis)

- mechanical and physical testing (tensile, impact, rheology, abrasion, aging)

- thermal analysis (DSC, TGA, DMA)

- advanced imaging techniques (SEM, TEM, AFM)

- nano-scale characterization (nanoindention/nanoscratch)

- structure characterization (WXRD, SAXS, micro-CT)

- surface analysis (XPS, Auger nanoprobe).

In addition, UA’s polymer experts partner with the University’s Department of Chemistry for the Magnetic Resonance Center, specializing in Nuclear Magnetic Resonance (NMR) techniques, as well as an advanced Mass Spectroscopy Laboratory. Run as separate units, they are close and important partners in external testing initiatives.

Dr. Randy Niedermier, vice president of the Technical Group at Preferred Compounding Corp. (now HEXPOL Compounding), said: “For years, Preferred Compounding (now HEXPOL Compounding) has used the services of APTS-Testing to complement its existing in-house lab capabilities. It has been a beneficial partnership as APTS-Testing has been able to provide us with professional results that are accepted and respected throughout the industry.”

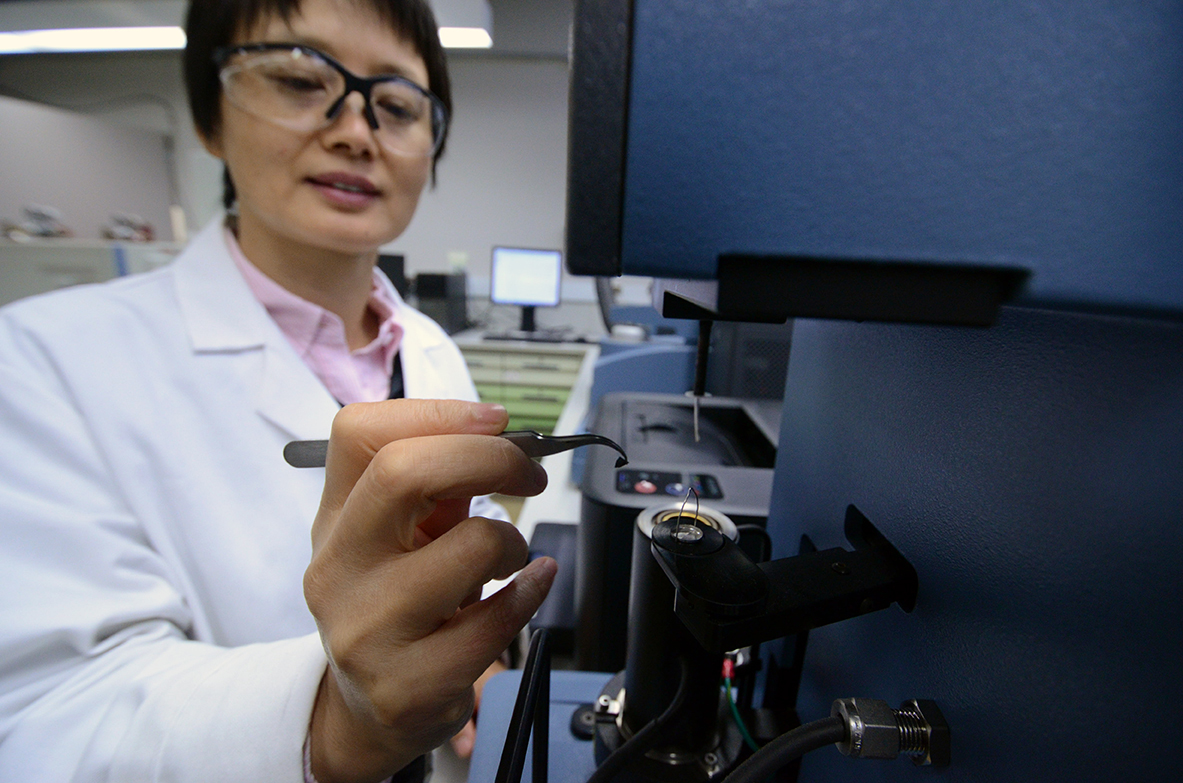

Yaohong Pang, polymer characterization specialist, analyzes polymers with a thermal gravimetric analyzer.

Media contact: Cristine Boyd, 330-972-6476 or cboyd @uakron.edu.