With a newly awarded grant of $295,501 from the National Science Foundation, Dr. Jae-Won Choi hopes to further advance 3D printing processes that can produce a wide variety of structures. The title of his research is “Multi-Scale 3D Printing Using Vat-free Photopolymerization.”

“Although many 3D printing processes are commercially available and technologies are mature enough to print complicated 3D structures, there are still limitations in achieving a large structure with micron features,” explains Choi, a tenure-track assistant professor in the Department of Mechanical Engineering.

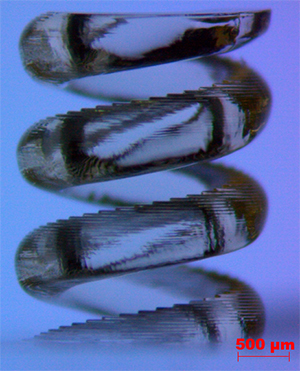

The NSF award will support the fundamental research needed on a new stereolithography process — the technique that builds up the structure of an object layer by layer. In Choi’s research, the material container is replaced by a liquid bridge formed between two optically clear plates using surface tension.

Many applications possible

“Research results could enable the development of low-cost, multi-scale 3D printers for manufacturing complex structures with micron resolutions on a large area,” says Choi. “Examples of such structures are 3D fluidics, sensors, actuators, drug delivery devices and tissue engineering scaffolds.”

Choi recently returned from Bali, Indonesia, where he attended the International Symposium on Green Manufacturing and Applications (ISGMA). The annual conference focuses on cutting-edge research on designs, products, manufacturing processes, materials and applications. Choi was given a Young Researcher Award for his 3D printing research.

Dr. Jae-Won Choi

A 3D printed spiral structure using liquid bridge microstereolithography.